Hydraulic Lift

Price 205000.00 INR/ Unit

MOQ : 1 Unit

Hydraulic Lift Specification

- Door Opening Size

- 700 mm 1200 mm

- Type

- Scissor / Goods / Passenger / Car Lift

- Car Dimension

- Customizable as per requirement

- Voltage

- 220V / 380V / 415V

- Pit Depth

- 150 mm 300 mm

- Noise Level

- 65 dB

- Machine Room Size

- Compact / Machine-roomless options available

- Hoist Way Size

- As per design and capacity

- Inclination

- 0 (Vertical Lift)

- Load Capacity

- Standard & Customized Available

- Overhead Height

- Minimum 2500 mm

- Usage

- Material Handling / Industrial / Commercial / Vehicle Movement

- Material

- Other

- Drive Type

- Hydraulic

- Power Supply

- 3 Phase AC, 50/60 Hz

- Speed

- 0.2 m/s 0.5 m/s

- Max. Lifting Height

- Upto 12 meters

- Max. Lifting Weight

- As per Model (Upto 5000 kg)

- Mechanism Type

- Hydraulic

- Working Temperature

- -10C to 55C

- Control Device

- Push Button / Remote Control

- Safety Device

- Emergency Stop, Safety Valve, Overload Protection

- Capacity

- Available in 500 kg to 5000 kg

- Installation

- Indoor / Outdoor

- Control Panel

- Microprocessor based

- Pressure Range

- 10-15 MPa

- Lifting Mechanism

- Single/Double Hydraulic Cylinder

- Lift Color

- Yellow & Grey (Custom colors available)

- Motor Power

- 3.0 kW

- Operation

- Automatic / Manual

- Platform Size

- Customizable as per requirement

- Hydraulic Oil Used

- 32 Grade or equivalent

- Finishing

- Powder Coated / Painted

Hydraulic Lift Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Delivery Time

- 3-4 Week

- Main Domestic Market

- North India, All India

About Hydraulic Lift

The best suitable places for hydraulic lifts to manage heavy loads are manufacturing plants, building sites, and other industrial environments. It comes in a range of designs and enhances the security and productivity of many materials handling tasks. Compared to other elevating techniques, our solution takes up less space inside a building roughly 10 less space is needed for the lift shaft. A hydraulic lift uses fluid pressure produced by an appropriate fluid. It is used to hoist cars in garages and gas stations. This item features two pistons that are separated from one another.

Flexible Platform & Design Options

The hydraulic lifts platform and car dimensions can be tailored to meet specific requirements, ensuring seamless integration into diverse industrial, commercial, or automotive environments. With a choice of yellow, grey, or custom colors, plus machine-roomless installation options, this lift adapts to your space constraints and aesthetic preferences.

Advanced Hydraulic Mechanism & Controls

Equipped with a single or double hydraulic cylinder, the lift guarantees smooth and efficient movement. The microprocessor-based control panel alongside push button or remote control operation enhances user convenience. The inclusion of emergency stop and overload protection further reinforces operational safety.

Powerful Performance & Reliable Operation

Supporting capacities from 500 kg up to 5000 kg and lifting heights up to 12 meters, this lift runs on a 3-phase AC power supply (220V/380V/415V) at 50/60 Hz, delivering a travel speed between 0.2 m/s and 0.5 m/s. Its versatile usage covers material transport, vehicle lifting, and more, with quiet operation ( 65 dB) and robust construction for long-term reliability.

FAQs of Hydraulic Lift:

Q: How do I select the appropriate hydraulic lift model for my requirements?

A: Choosing the right hydraulic lift involves considering your application (material handling, goods, passenger, or car transport), required platform size, weight capacity (500 kg5000 kg), lifting height (up to 12 m), and installation location (indoor or outdoor). Our experts can assist in customizing dimensions, finishes, and control options to best suit your needs.Q: What is the installation process for these hydraulic lifts?

A: Installation typically starts with a site assessment to determine hoist way, pit depth, and overhead clearance. The lift can be configured for compact or machine-roomless setups. Our team manages the installation from delivery and assembly to commissioning, ensuring compliance with safety standards and precise operation.Q: When is maintenance required, and what servicing support is available?

A: Routine maintenance intervals depend on lift usage, but general inspections are recommended quarterly. We provide full service support, including inspections, hydraulic oil checks (32 grade or equivalent), lubrication, and performance testing. Our network across India ensures reliable after-sales service and spare parts availability.Q: Where can these hydraulic lifts be installed?

A: These lifts are suitable for both indoor and outdoor environments such as warehouses, factories, commercial complexes, car showrooms, and industrial facilities. Designed to withstand temperatures from -10C to 55C, they perform reliably in varied Indian climatic and usage conditions.Q: What are the benefits of using a customizable hydraulic lift?

A: Customizable design allows for precise adaptation to your facilitys dimensions, operational workflow, and aesthetic requirements. Benefits include improved safety, efficient material handling, versatility in usage (from goods to passenger movement), space optimization, and compliance with quality and safety standards.Q: How is the lift operated and what safety features are included?

A: The lift can be controlled automatically or manually, using a push button or remote control. For user protection, it includes an emergency stop, safety valve, and overload protection mechanisms, ensuring safe operation during routine use and emergencies.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Lift Category

Scissors Lift

Price 70000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Usage : Other, Material Lifting / Warehouse / Industrial

Passenger Lift

Price 305000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, As per Client Requirement

Usage : For Passengers Loading

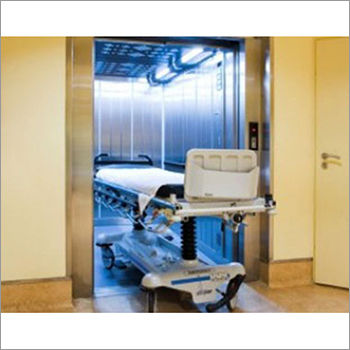

Hospital Lift

Price 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Usage : Medical Elevators

Goods Lift

Price 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other

Usage : Freight Elevator, Building Elevator, Medical Elevators

|

PREETAA ELEVATORS INC.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry